Unison Tek had made many customized extrusion metal parts for over 30 years, especially in aluminium. We not only provide aluminum extrusion machining parts, but also provide fast delivery with DHL to you. And 50% shipping discount for our new client at first order.

Tolerance Accuracy

Materials

Material |

| Aluminum Extrusion Grades: AL6063, AL6061, AL6082, AL6060, AL5052 |

| Brass Extrusion Grades: C3771 & C3604 |

Basically, the MOQ for aluminum extrusion & brass extrusion is around 300kg. Common material serial numbers of the 6000 series we have here for aluminum extrusion are in the table above.

Note that AL5052 has relatively more restriction in the forming process.For Brass Extrusion, we have currently done C3771 & C3604, but there should be more. Feel free to consult with us if you require other grades for extrusion.

Metal Finish |

| Standard Minimal post processing are done upon request. |

| For Aluminum Extrusions Anodizing thickness 12-15 µm. Hard Anodizing thickness above 40µm. Can be done with gloss & matt, provide samples to match for. |

| Glass-bead Blasting Surface is left with a smooth matt surface. Abrasive particle size 100, 120 micron. We can also work on other grit sizes, name one and we will try accommodate your requirement. |

| Custom Feel free to consult with us about other types of surface treatments if needed. |

The Process of Aluminum Extrusion

The process of aluminum extrusion consists of the following steps:

- After designing and forming the shape of the die, a cylindrical billet of aluminum alloy is heated to 800°F-925°F.

- The aluminum billet is then transferred to a loader, where a lubricant is added to prevent it from sticking to the extrusion machine, the ram or the handle.

- Substantial pressure is applied to a dummy block using a ram, which pushes the aluminum billet into the container, forcing it through the die.

- To avoid the formation of oxides, nitrogen in liquid or gaseous form is introduced and allowed to flow through the sections of the die. This creates an inert atmosphere and increases the life of the die.

- The extruded part passes onto a run-out table as an elongated piece that is now the same shape as the die opening. It is then pulled to the cooling table where fans cool the newly created aluminum extrusion.

- When the cooling is completed, the extruded aluminum is moved to a stretcher, for straightening and work hardening.

- The hardened extrusions are brought to the saw table and cut according to the required lengths.

- The final step is to treat the extrusions with heat in age ovens, which hardens the aluminum by speeding the aging process.

Today, aluminum extrusion is used for a wide range of purposes, including components of the International Space Station. These diverse applications are possible due to the advantageous attributes of aluminum, from its particular blend of strength and ductility to its conductivity, its non-magnetic properties and its ability to be recycled repeatedly without loss of integrity.

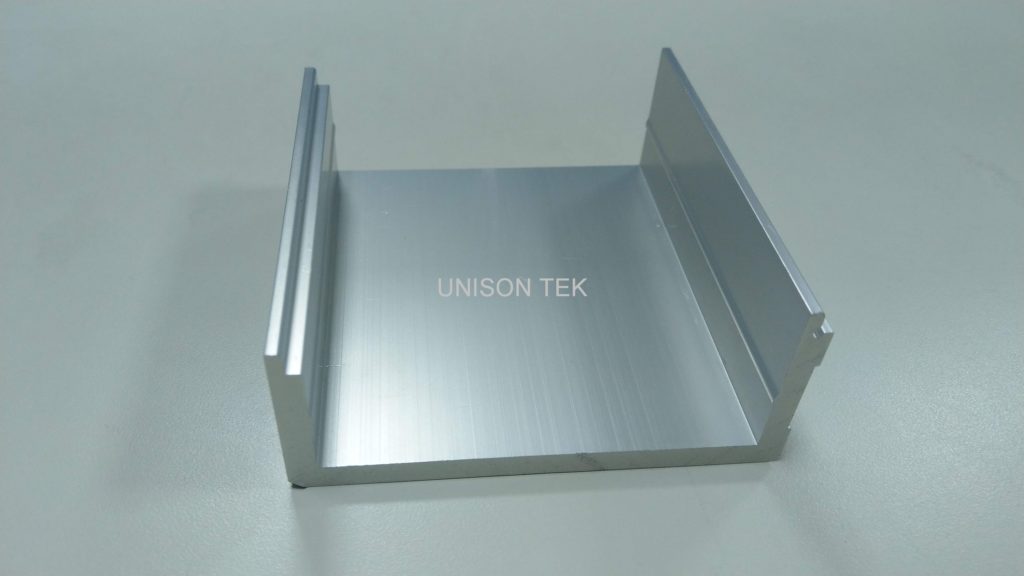

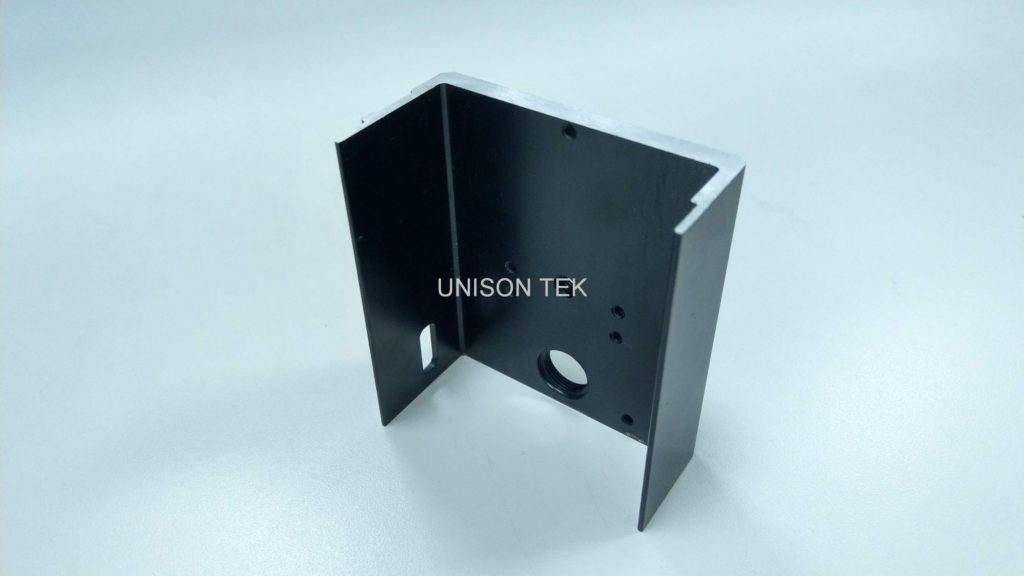

Following are Precision Extrusion Metal Parts We Made

All of these capabilities make aluminum extrusion a viable and adaptable solution for an growing number of manufacturing needs.

Get more info about CNC Machining Parts, CNC Turning Parts, CNC Milling Parts,

or Contact us, e-mail to Harry Yen [email protected]