Name of Fine Blanking

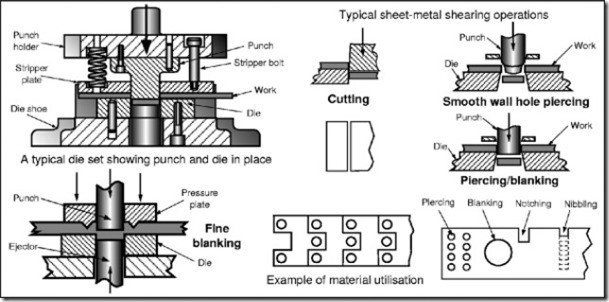

Precision blanking (also known as fine blanking) is a special type of stamping process that produces parts with higher precision, flatness and edge characteristics than conventional stamping.

Brief Intron of Fine Blanking process

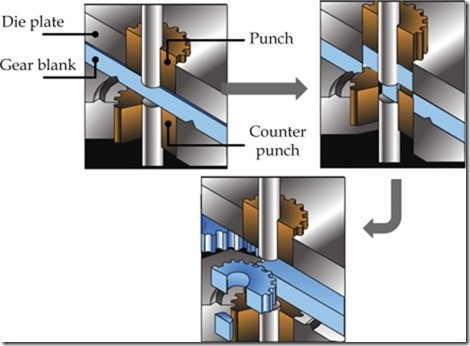

Fine blanking is similar to extrusion in which metal is extruded through a cavity to form the desired gear tooth geometry. It is also similar to stamping, but differs in the sense that two opposing dies are used to form the gears from the sheet.

The fine working principle of a typical spur gear. Initially, the gear blank in the form of a sheet is compressed between the blank holder and the mold. The impact ring in the bottom mold resists the inflow of radial material. The punch then moves up until the gear is fully cut.

Then the counter-shoot is lowered, the punching pressure is reversed, the punch is retracted, the gear is removed, and the machine is ready for the next cycle.

This method is suitable for mass production of spur gears. This process can be extended for the manufacture of helical gears (rotary precision blanking) by providing additional rotational movement of the punch and the counter punch.

Precision blanking can be used to make bevels, multiple and complex gear sets that are difficult to produce by stamping. Gears made by precision blanking have excellent dimensional accuracy and surface finish, and have relatively higher strength than gears manufactured by stamping and powder metallurgy.

Fine-punching gears have a wide range of applications, including automobiles, office equipment, electrical appliances, medical equipment, electronic equipment, etc.

Visit our others pages Products, Facility, Inspection Equipments