In general, the stamping process can be divided into "shearing and shearing", "punching", "bending", "forming", etc., and these steps are separately placed in each mold and pressed to complete the stamped product. This stamping procedure must be completed by multiple sets of molds or multiple projects to complete a complete stamped product.

Therefore, the R&D and design capabilities of the "Stamping Engineering" are high and low (that is, when you get the stamped product/picture, you must check the size, shape, characteristics, tolerances of the product, and evaluate how the design combines continuous mold, engineering mold, and composite mold. ), has a large impact on the production efficiency and production cost of stamped products.

The production and selection of different projects can produce complex shapes. From the design of the engineering mold set, we can understand the level of theproduction of the workpiece and the development capability of the R&D designers.

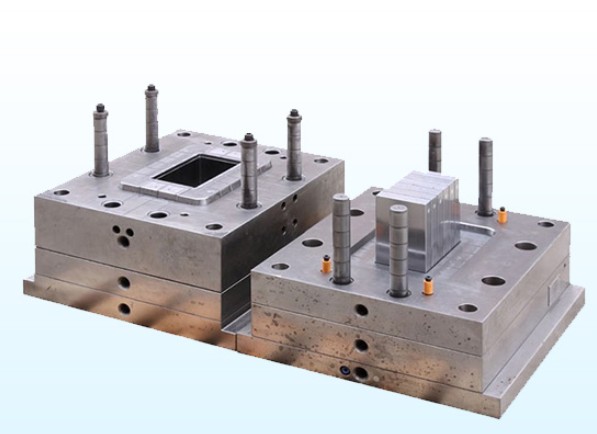

Engineering model

"Single engineering mold" is the individual mold in the process of completing this stamping product. The “single engineering model” is only stamped for one or more features, and one set of molds uses one punch.

This is the most common stamping die, with only one station to complete a production process. This mold is common in application, simple in structure, easy to manufacture, but low in production efficiency.

Compound mode

In order to improve production efficiency, multiple stamping processes, such as cutting, blanking, punching, and edging, can be arranged on the same mold to complete multiple stamping operations at one station. This type of mold is called "composite." mold".

Continuous mode

It is a combination of multiple engineering molds; that is, a plurality of stamping processes in the engineering mold are formed, and a series of different stamping processes are completed in one stroke of the punching machine, and the punching machine feeds the material forward according to a fixed step.

Move, so that a number of processes can be completed on a pair of molds, generally punching, blanking, bending, trimming, stretching and so on.

To design continuous molds, attention should be paid to the spacing between the modules, the machining accuracy of the parts, the accuracy of the assembly, the accuracy of the matching, etc., in order to achieve the goal of continuous automated mass production.

This can greatly improve production efficiency, but the maintenance technology requirements of the mold and machine are relatively high. Controls need to be controlled at any time to maintain consistent quality.