When it comes to precision machining, every tiny detail matters. Even the smallest mistake can lead to parts that don’t fit or work properly.

One of the most important — but sometimes overlooked — factors is choosing the right cutting tool and controlling how it wears out over time.

Why Tool Selection Matters

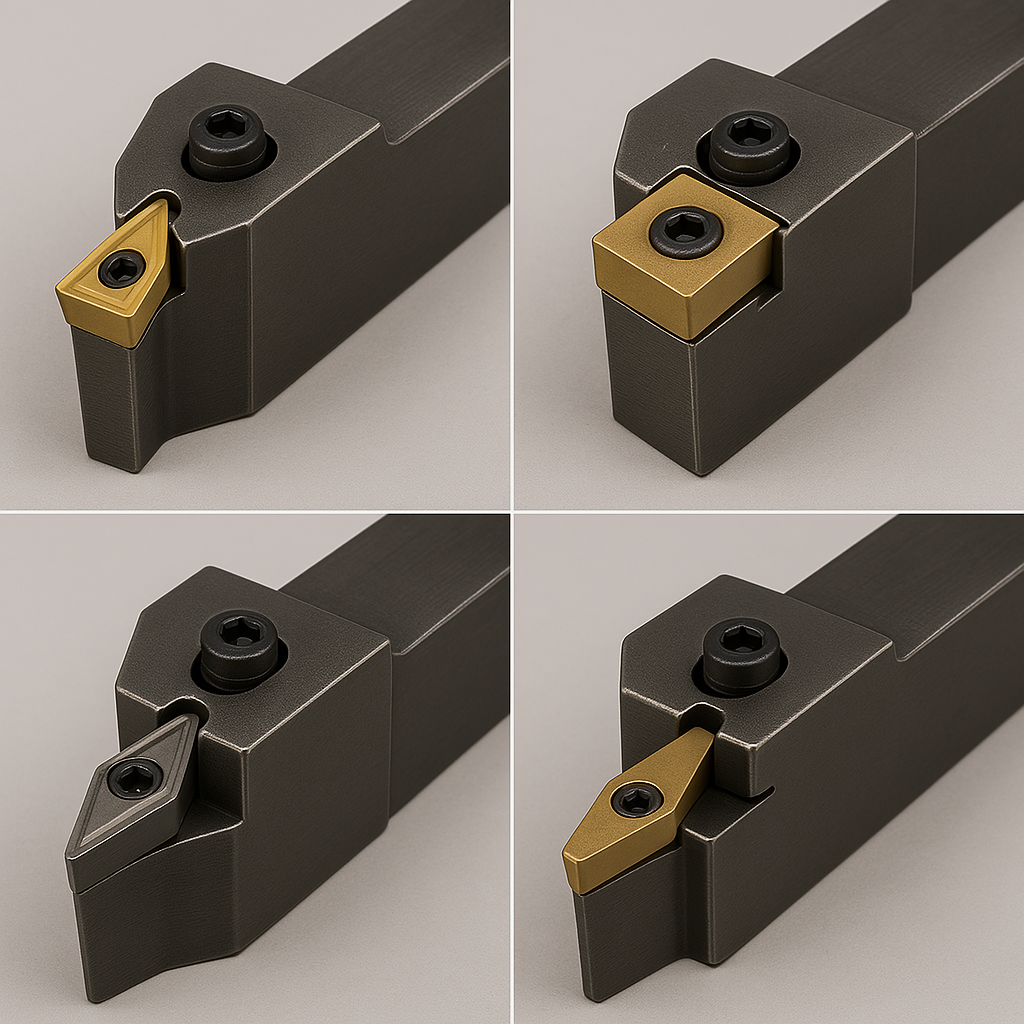

In precision machining, cutting tools are like the "hands" of the machine. If the tool isn’t right for the job, it doesn’t matter how advanced or expensive the machine is — the results won’t be good. Choosing the correct tool involves thinking about:

Material of the Part: Different materials (like aluminum, steel, or titanium) need different types of tools.

Tool Material: Common options include high-speed steel, carbide, or even diamond-coated tools, depending on how hard the material is.

Cutting Conditions: Factors like cutting speed, feed rate, and depth of cut also influence which tool works best.

Using the right tool helps to:

Make cleaner cuts

Maintain tight tolerances

Reduce vibrations and heat

Extend the tool's life

The Problem of Tool Wear

Even the best tool doesn’t last forever. As a cutting tool is used, its edges slowly wear down. This is called tool wear, and if it’s not managed properly, it can lead to:

Poor surface finish

Inaccurate dimensions

More scrap parts

Machine damage

There are several types of tool wear, such as:

Flank wear: The side of the tool gets worn.

Crater wear: The cutting edge develops pits or craters.

Chipping or breakage: The edge cracks or breaks suddenly.

How to Control Tool Wear

To keep machining processes running smoothly, manufacturers use several strategies to control tool wear:

Monitoring: Regularly check tools for wear using inspection tools or automatic sensors.

Coolant and Lubrication: These reduce heat, which is a major cause of wear.

Proper Speeds and Feeds: Running the machine at the right speeds can greatly extend tool life.

Using Coated Tools: Special coatings (like TiN, TiAlN, or diamond) help protect the tool surface.

The Payoff: Better Precision and Efficiency

When tools are carefully chosen and well-maintained, the benefits are huge:

Consistent Quality: Parts meet exact specifications every time.

Longer Tool Life: Fewer tool changes and lower costs.

Less Downtime: Machines keep running smoothly.

Higher Productivity: Faster cycle times without sacrificing accuracy.

Summary

In precision machining, choosing the right tool and keeping it in good shape is just as important as having a good machine or a skilled operator.

With smart tool selection and careful wear control, manufacturers can produce high-quality parts efficiently and avoid costly problems. In the end, attention to these small details leads to big success.

Please get more information, please visit our CNC Turning Parts or Products.

Contact us for your customized metal parts.