An aluminum extrusion part is a component formed by forcing heated aluminum alloy through a shaped die to create a continuous profile with a uniform cross-section.

This process allows for the production of complex shapes that are lightweight, strong, and corrosion-resistant, making them ideal for various applications across industries.

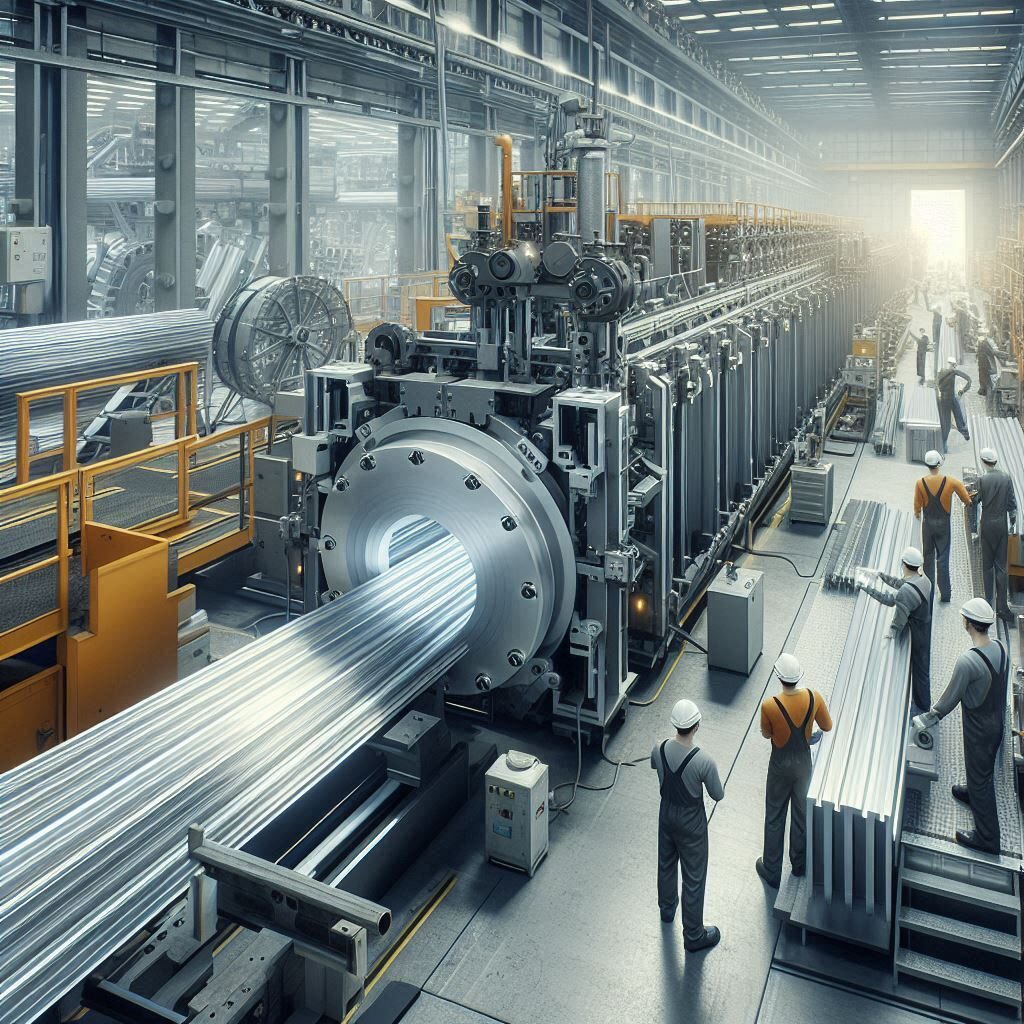

The Aluminum Extrusion Process

- Preparation of Aluminum Billet: A cylindrical aluminum billet is heated to approximately 900°F (482°C) to soften it, making it more malleable for the extrusion process.

- Extrusion Through Die: The softened billet is placed into a hydraulic press, which applies pressure to force the aluminum through a die. The die's shape determines the cross-sectional profile of the extruded part.

- Cooling and Quenching: After extrusion, the part is cooled using air or water to solidify it and set its mechanical properties.

- Stretching and Straightening: The extruded part may be stretched to straighten it and relieve internal stresses, ensuring dimensional accuracy.

- Cutting to Length: The extruded and straightened part is then cut to the desired length using precision saws.

- Surface Treatment: Depending on the application, the part may undergo surface treatments such as anodizing, painting, or coating to enhance its appearance and resistance to corrosion.

Common Applications

- Construction: Used in window frames, curtain walls, and structural components.

- Automotive: Employed in vehicle frames, heat exchangers, and trim parts.

- Aerospace: Utilized in aircraft structures and components.

- Electronics: Serves in heat sinks and enclosures.

- Consumer Products: Found in furniture, sporting equipment, and appliances.

Advantages of Aluminum Extrusion Parts

- Lightweight: Aluminum's low density makes the parts easy to handle and reduces transportation costs.

- Corrosion Resistance: Natural oxide layer provides resistance to corrosion; surface treatments can enhance this property.

- Design Flexibility: Ability to create complex and custom profiles to meet specific design requirements.

- Strength-to-Weight Ratio: Offers a high strength-to-weight ratio, making it suitable for structural applications.

- Sustainability: Aluminum is 100% recyclable without losing its properties, supporting environmental sustainability.

Please visit our pages CNC Turning Parts、CNC Milling Parts、CNC Machined Parts