Sister Company We Cooperate With

Unison Tek has a valued sister-company that is specialized in mold design, manufacturing, development, stamping production OEM processing. The facility provides aerospace parts processing, military parts processing, remote control aircraft manufacturing, hardware parts processing, mold manufacturing.

For military equipment, we are capable of making ammunition belt for machine gun by our machining service and the shell of gun is made by our plastic injection factory.

If you need any support, please feel free to contact Harry Yen [email protected]

Over the past few years, our affiliated factory has collaborated with aerospace and defense industry companies in the U.S. and manufactured premium military equipment for them. Most important of all, our clients are satisfied with the quality and our service.

History

- Founded in 1993 in Taiwan.

- SGS ISO 9001 (Design and mold and process manufacturing technology product software)

- AIDC certificate in Taiwan, S-200 Supplier Quality System

- ISO9001 certificate(International Quality Certification)

- AS 9100C (Aviation Industry Quality Management System Certification)

- Nadcap (Certification of special products and processes in the aviation industry)(Wire EDM)

- So far, there are about 80 employees in the company.

Products

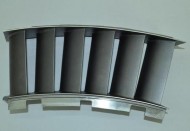

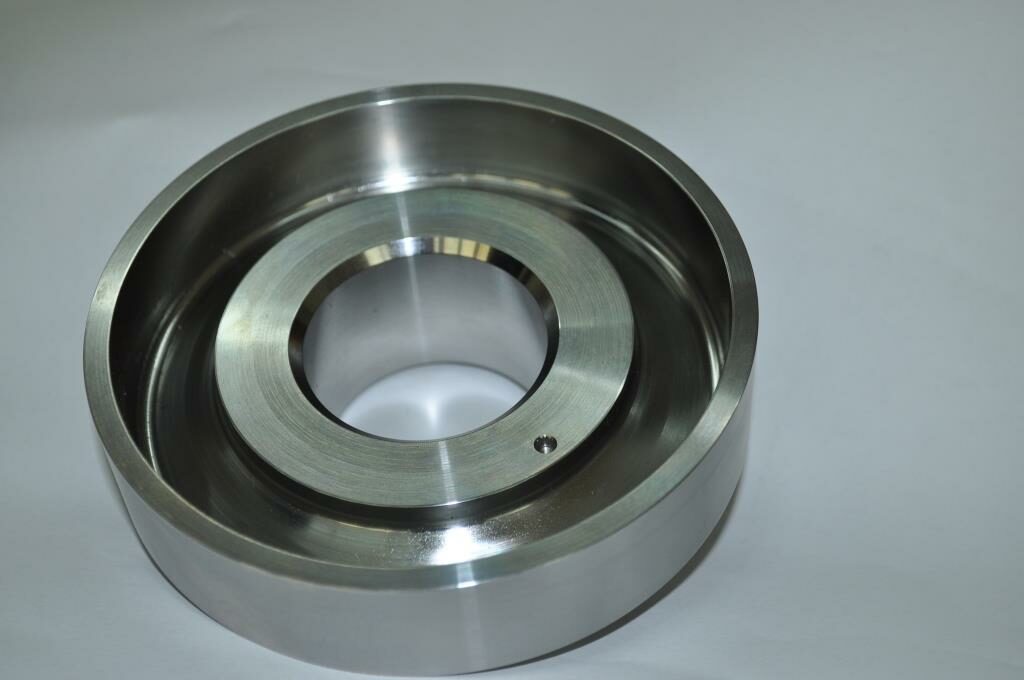

Precision Parts

Stamping Parts

Stamping Parts

Extruded/Extrusion Parts

Facility

Vertical Lathe

7 set, Max: ø1600 , Min: ø800

cnc horizontal turning

4 set, Max: ø520 , Min: ø39

Machining center

2 set, 4 axis half, max processing: 2000mm

Mazak-machining-center

1 set, 5 axis, Max: ø1450

Mazak-machining-center

1 set, Max dimension: 1045mm

CNC Surface Grinding Machine

7 set

complex turning & milling

2 set

CNC Milling Machine

8 set, Max: ø1100, Min: ø635

CNC Milling Machine

SEIBUEDM Wire Cut EDM

Max dimension: 450×600×250mm

Sodick Wire Cut EDM

Max dimension: 550×380×280mm

Molding-Press

Machine tonnage: 160、110、80、45、40、250

Inspection Equipment

Software the company used

- CATIA V5:R2015 and R2016

- NX13430:CAD/CAM (Five-axis machining module)

- TopSolid:1.CAD/CAM (Five-axis positioning module)

- Sheet metal design (continuous mode) module

- FTi (Moldability analysis module)

Facility the company used

SHEFFIELD Pioneer CMM

1200 x 1000 x 800 mm

Coordinate Measuring Machine

Model:TESA micro hite 3D DCC

440 x 500 x 410 mm

Zeiss-ACCURA-CMM

2000 x 3000 x 1500 mm

CHIEN WEI PRECISE Projector

250x150x200 mm ( X,Y,Z)

TRIMOS Height Gage

Dimension Area:0~600/0~24"

Our Goal to Great

In the era of ever-changing technology information, we continue to transform and improve technology.

We maintain professional and innovative design, precise manufacturing, rapid tool change and user-friendly, user-friendly touch window for easy operation, whether in stand-alone operation or in a hybrid automatic production line. There is great and fairly good compatibility.

With the aim of precision, speed and quality, the company's customer-oriented service attitude and customer-oriented spirit continue to develop and provide customers with the best quality and professional services.