Lathes have been in use since Ancient times in BC by the Greeks and Chinese. At the beginning it was tedious and needed a lot of stamina for the “machinists”, since everything was done by hand.

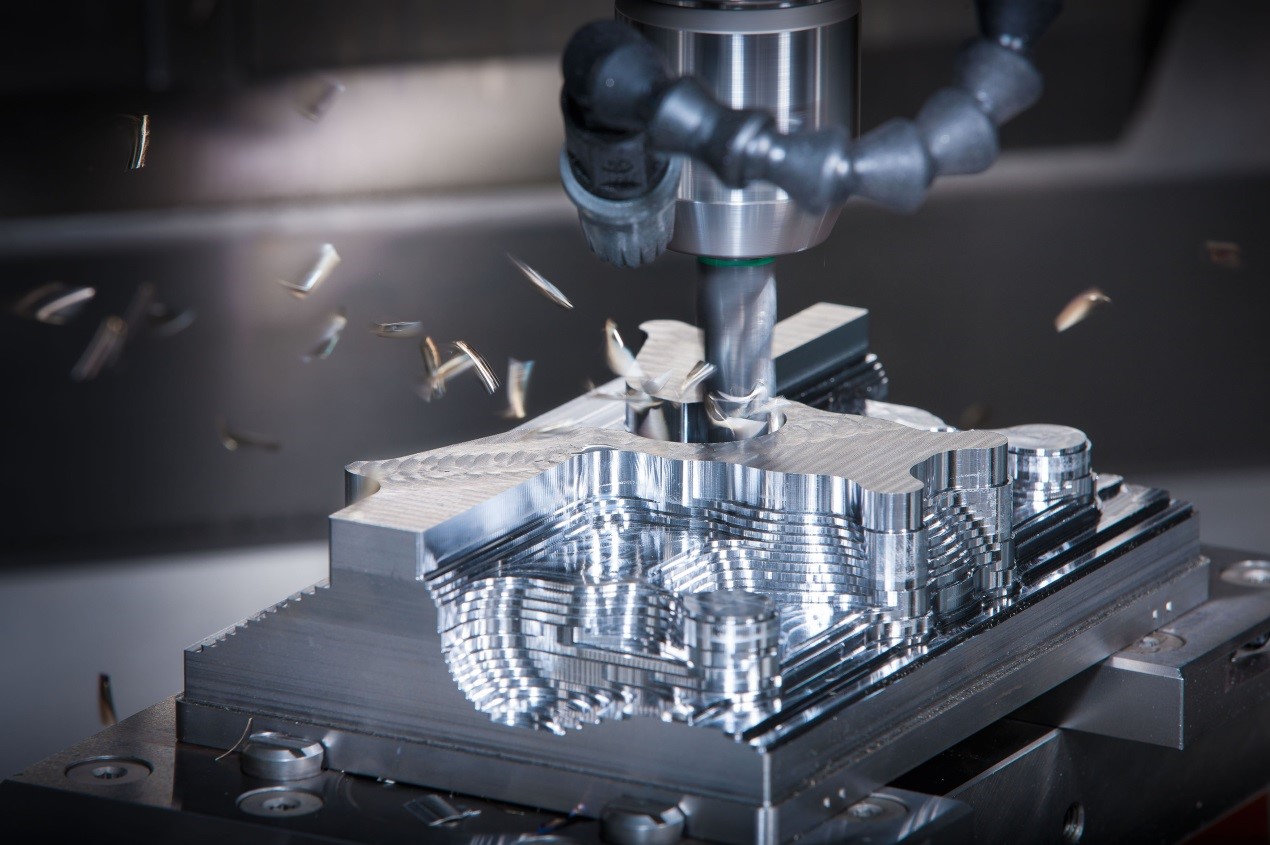

However, with the invention of computer numerical controlled (CNC) lathes, our generation of lathe operators in UNISON TEK especially can rely on sophisticated computer control systems to make complex tasks quickly and reliably.

The lathe machine basically combines rotation and cutting to shape and smooth materials, that’s make it efficient and cost effective.

How Does It Work?

At the factory in the early version of lathe process, two operators secure a piece of raw material and place it securely inside the lathe clamp. The lathe spins either vertically or horizontally, controlled by one person, and the other shape the material with cutting tools.

Later on, a single person can do both, lathe and shape the material, thanks to the development of foot-powered wheels and water wheels. The game changes when motorized lathes that use electricity came to the market, make it easier and more efficient.

The industrial production processes became easier with the invention of lathes in the modern automation. Lathes can be use in different industry, from a tiny version use by jewelers and watchmakers or enormous industrial machines. The most common material used are wood and metal, other materials like glass can be shape by a lathe as well.

To design and execute a project at Unisontek of different shapes and sizes, a CAD software with an intuitive interface can be use for the computerized lathe to follow.

The automation industry is huge and multiple parts need to be made with exact details and specifications, CNC automation with CAD software is beneficial at this stage. Most importantly that saves time during manufacturing process.

What Can we Make by using Lathe?

Cylindric and spherical shape that has a lot of details are mostly made by using lathes. In the automation industry CNC lathes is important, parts make for cars such as brake drums can be made easily and replacement part for machines and engines can be lathed as well.

We are now able to develop most complex parts and products with perfection and minimum effort with CNC machining.

Please feel free to contact us at Unison Tek if you have any inquiry that need CNC machining process.