Aluminum Extrusion

Aluminum extrusion technology in modern industries, both in Unison Tek & elsewhere, continues to be a vital subject of discussion and evaluation concerning its application to the working environment.

The demand for and application of aluminum extrusions in architecture and in the manufacture of automobiles, small machine components, structural components and especially aerospace parts, have increased tremendously, and competition in this industry is intense. The extrusion industry is now more than ten decades old.

Continuing education is needed to upgrade knowledge about aluminum extrusion technology, both in the academic and industrial communities. Therefore, we are here writing to provide many developed ideas, more practical and useful theoretical concepts based on knowledge acquired from research and academic work, industrial working experience, and the review of research and technical papers related to aluminum extrusion technology.

This Article provides a comprehensive introduction to the explosion of information that has become available in the field of aluminum extrusion technology during the last fifteen or twenty years.

The topics are designed in such a way that this article provides adequate information for the newcomer without boring the expert.

Topics are presented with a balanced coverage of the relevant fundamentals and real-world practices so that the relevant person in the aluminum extrusion industry develops a good understanding of the important interrelationships among the many technical and physical factors involved and how engineering science impacts on practical considerations.

The ten chapters cover almost all the branches of aluminum extrusion technology.

In the past 18 years, a tremendous amount of technological advancement in aluminum extrusion technology has taken place worldwide, and this information is included in this book, Aluminum Extrusion Technology.

Furthermore, certain new topics with updated information have been added and described in some detail. This book also provides the key to further information and emphasizes important research and technic papers that are worthy of further study.

Knowing the Aluminum Extrusion Process

Aluminum extrusion is the process via which the raw aluminum material is pushed or thrusted very forcefully through a series of dies for producing desired shapes like a frost cream.

As it is well-known to the people of metal industry, metal such as aluminum is the most plentiful substance and element of the metal group that can be found in the earth’s crust. It is always found in the raw form in which it is found in the earth’s surface and it is popularly known as Bauxite, it is an alloy made up of aluminum, O2 and other metals and elements.

The most normal misconception is that it is not a pure metal.

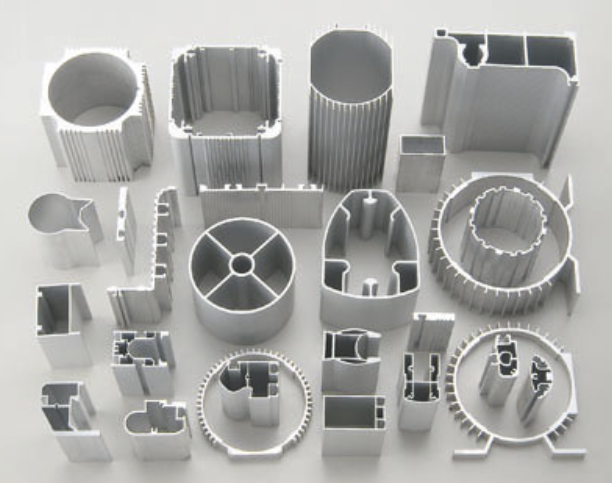

Aluminum Extrusion Dies

There are a variety of advantages for Aluminum extrusion that says that it is such a light metal that is comparatively light weighted whenever it is compared with other metals. Its weight is just one-third of them.

Since it weighs so much lighter, extrusions are naturally easier to handle & less expensive to ship. These corporal traits also make it further attractive for applications in fields where minimizing weight is essential such as aerospace & high risen building projects.

There are some other benefits of aluminum based materials that makes the aluminum profile very strong, during the procedure, this particular method can be made as strong as necessary as most applications.

This is predominantly true for cold weather applications because a metal such as aluminum eventually gets very stronger as the temperature falls. It is also secured by its own logically occurring oxide film.

Feel free to contact us at: [email protected]

Tel: 886-2-2298-8665 #221