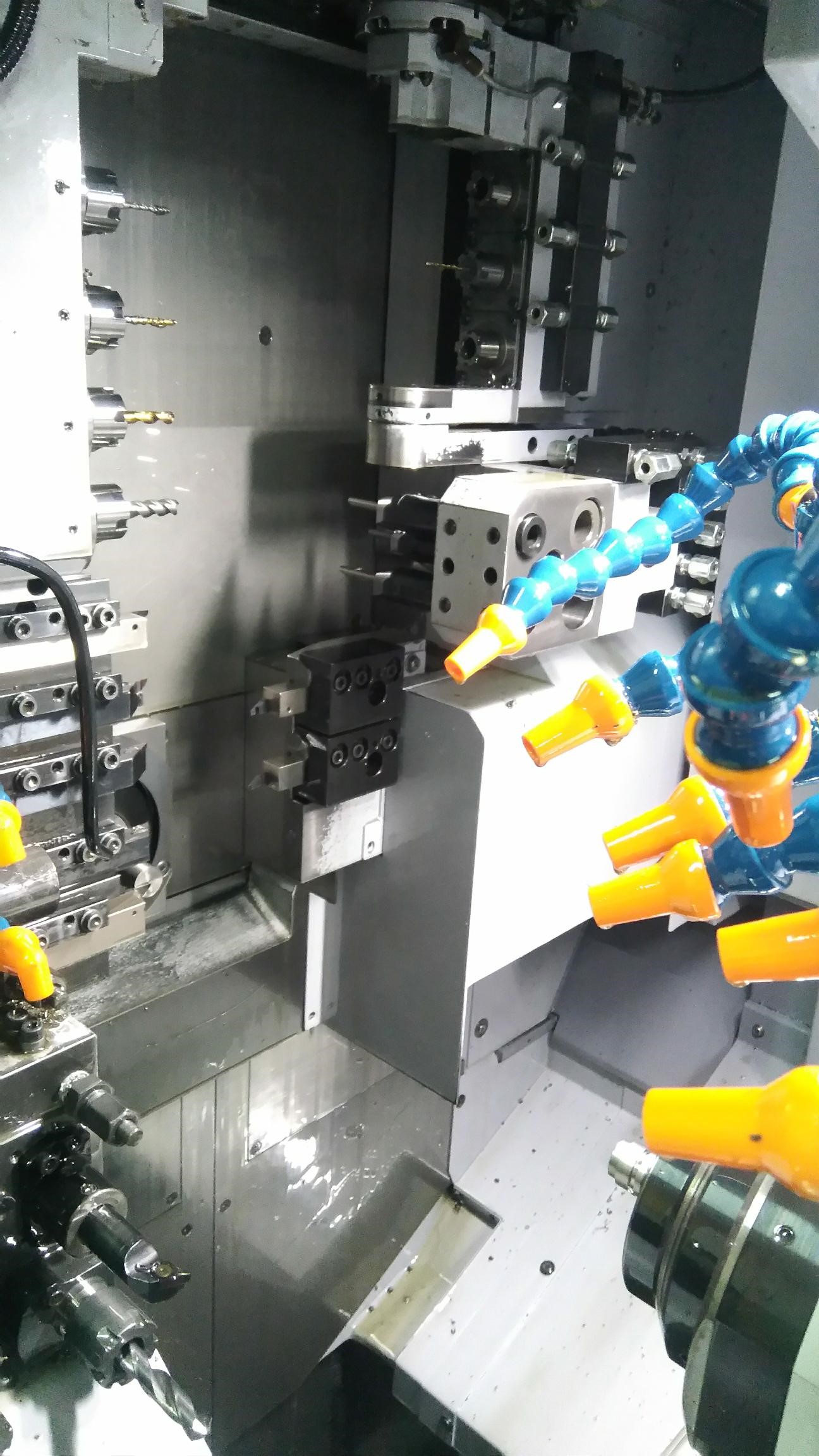

CNC machines have a high degree of complexity which help to make even the most sophisticated machining parts. It is important to have preventive maintenance program for your CNC machines to prevent costly repairs and downtime.

If you use your machine every day, no matter for Turning parts or Milling parts, it is crucial to properly maintained by human operators, to prevent expensive repairs. Let’s see some maintenance task to perform that can keep your CNC machine in good condition depending on how many hours your machines are running for.

Check Your Machine’s Fluids

It is important to check that there are enough hydraulic fluids and lubricants that need to be replaced or replenish from time to time. Ensure that you inspect your machine’s user manual to make sure what it needs and when.

You should also monitor that the machine is not using too much fluid as it should be, that might be a sign of underlying issues.

Grease Moving Parts

Greasing the moving part of your CNC machine regularly is crucial to prevent them from experiencing excessive wear. Monitor them from time to time in a way to find out any dry spots, so that you don’t need to grease them every time you use your CNC machine. This practice will help you prevent unwanted wear and save you some profits.

Clear out Your Machine

It happening to every CNC machine to have grime and scrap material pile up on its exterior, keep it clean by simply taking a rag and wiping it down once daily. Your CNC machine will look more presentable to show to your clients and remove all debris or residue that could cause any mechanical issues later.

Here at Unison Tek

Following these simple steps have helped, our engineers at Unison Tek have ensured that our CNC machines maintain reliable and stable production for long periods of time. It is our pleasure to welcome you to visit us and tour our facilities.

Feel free to contact us at georges@unisontek.com.tw for more information!