In the verge of 3D printing methods, a lot of comparison with CNC machining has been given attention between these two, although they operate very different from each other. 3D printing basically builds things via layers;

However, CNC machining uses the way to carve a material to a desired object shape when is programmed. They are tow different printing methods, let’s outlined some advantages and disadvantages for CNC machining and 3D printing.

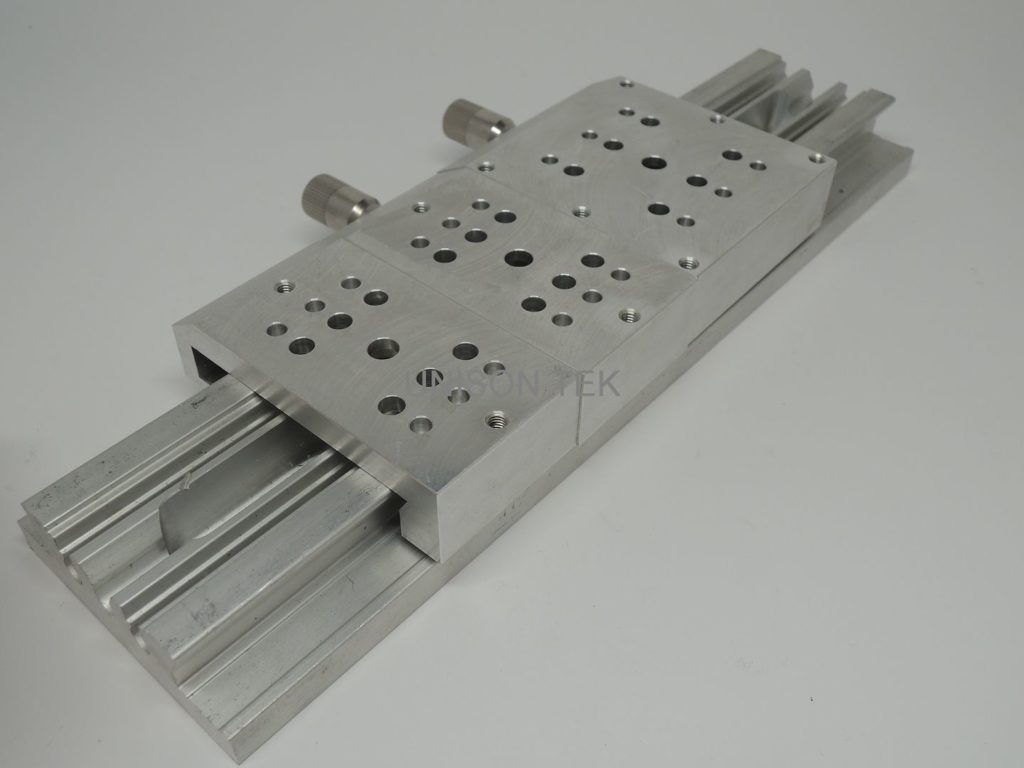

To manufacture an object with CNC machining process (or CNC milling), a customized computer program is created, this method also controls several factors such as location, feed rate, coordination and speeds.

CNC machining brought a lot of precision with exact positioning which leads to a better standard of accuracy. It is also mating accuracy and very easy for repetitive manufacturing. Another advantages for CNC machining are possible to work with a large variety of material such as plastic, metal, wood and wax as well as several others.

Running a mass production CNC machining is faster 3D printing. The process of CNC milling can be sped up, so when it comes to manufacturing speed 3D printing has the lower hand. When running a project in prototype stage it’s always nice to complete the task with speed rather than accuracy to speed up the development phase, that is one of the benefits of CNC milling.

One of the disadvantages of 3D printing is that it requires more manpower to design, operate and maintain production. Set up cost is another issue, which make 3D printing become inferior to CNC machining.

Unison Tek Co. Ltd. can help if you’re looking for a way to take your business to the next level, With our professional engineering and production team. For more information on any of the products we offer, contact us today!

Welcome to visit our Facility, Inspection Equipment, Products