Brief Intro

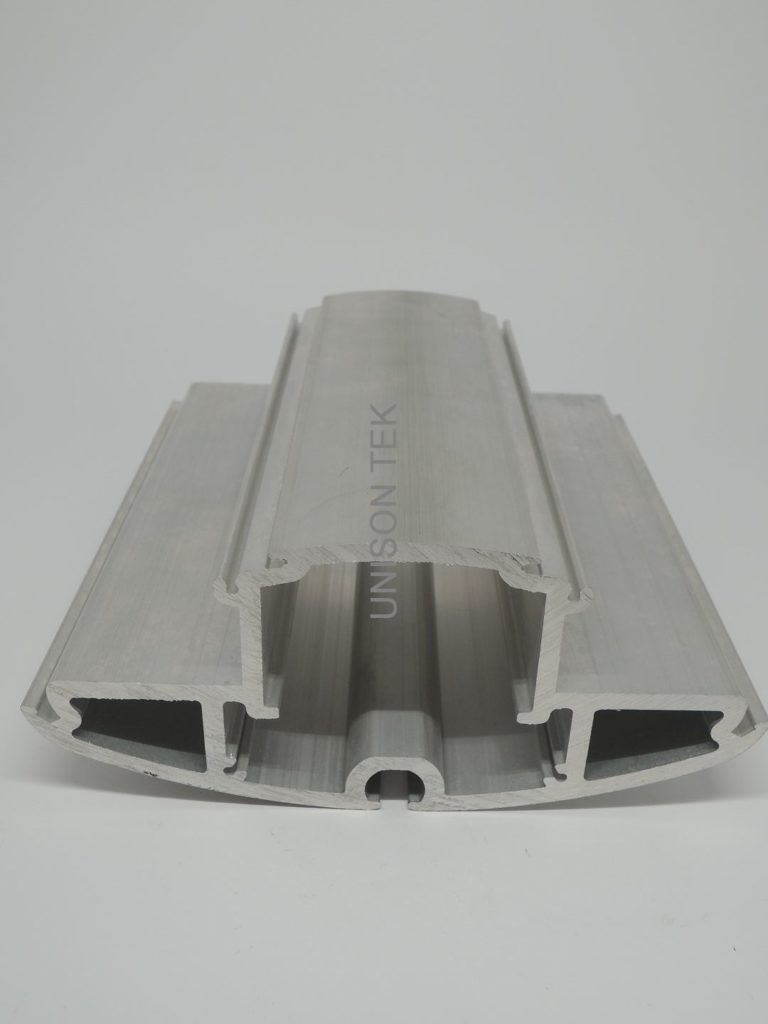

The extrusion process begins with the blank, which is an extruded alloy material. The blank must be softened by heating before extrusion. The heated billet is placed in an extruder, a powerful hydraulic device that pushes a module that forces the softened metal through the precision opening to create the shape you want.

Tolerance

According to your drawings, our tolerances range from 0.10mm to 0.05mm.

Process

Additional complexity can be applied during this process to further customize the extruded parts. For example, to form a hollow portion, a pin or perforated mandrel is placed within the mold. After the extrusion process, there are a number of options for adjusting the color, texture and brightness of the aluminum alloy surface. This may include aluminum anodizing or painting. Today, aluminum extrusion is used in a variety of applications, including components of the International Space Station. These different applications are possible due to the advantageous properties of aluminum. From its special blend of strength and ductility to its electrical conductivity, its non-magnetic properties and its ability are repeatedly cycled without loss of integrity. All of these features make aluminum extrusion a viable and adaptable solution to meet growing manufacturing needs.

If you have further requirements, please send the e-mail to [email protected]

See our Facility and Inspection Equipment