What is Forging ?

Forging is a process that uses pressure to change the shape of a metal material to meet the corresponding requirements. According to the temperature of the work piece during processing, the forging can be divided into hot forging, cold forging, warm forging, and the like.

According to the work piece temperature, it can be divided into: hot forging (above recrystallization temperature ~ below solid phase line); cold forging (forming at normal temperature); warm forging (between hot forging and cold forging).

Usually, after the billet is heated, it is hammered or pressed by a hand hammer, a hammer or a press to plastically deform it into a work piece of a certain shape and size.

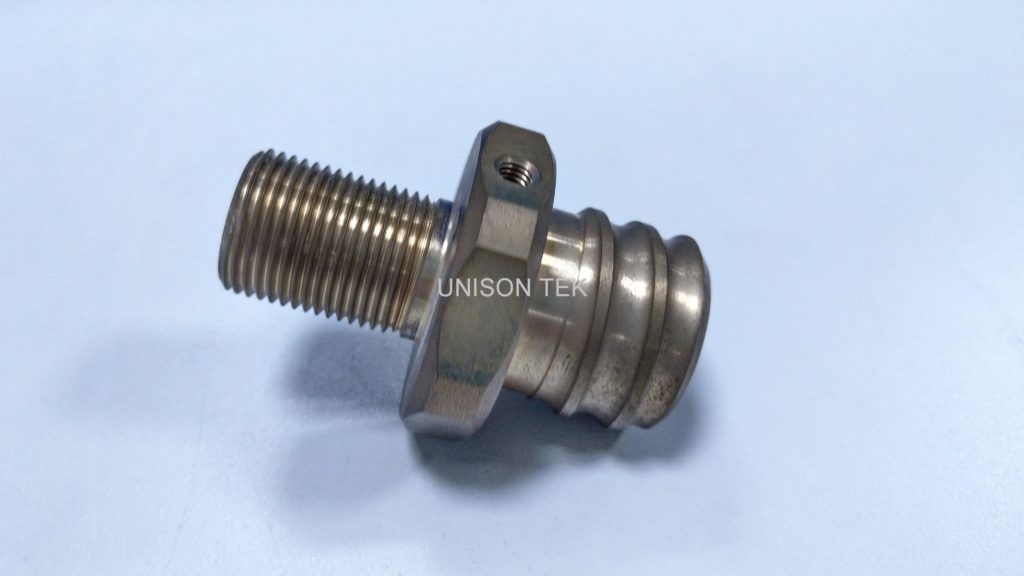

The obtained work piece is called a forging, and the forging can change the metal structure and improve Its mechanical properties are therefore commonly used in mechanical manufacturing to make parts that withstand large loads.

Forging metal materials

- Aluminum Alloy Aluminum Alloy

– 1000, 2000, 5000, 6000, 7000 series

- Titanium Alloy Titanium Alloy

– Mainly 65Ti

- Magnesium Alloy Magnesium Alloy

– AZ61 / AZ80 / ZK63

- Steel Metal Steel Alloy

– Various

- Copper Alloy Brass Alloy

– Various

See our Facility and Inspection Equipment