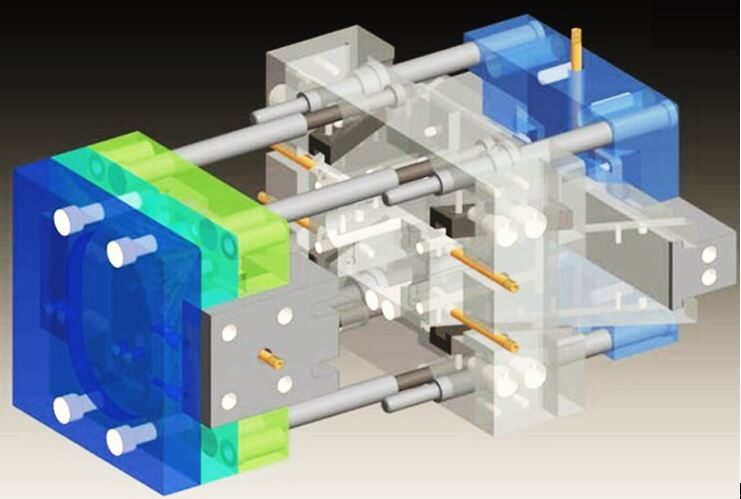

The plastic injection mold needs specific mechanisms to handle complex features or unique requirements in product design, ensuring smooth molding processes. Here are common necessary mechanisms:

Slider:

Used for molding features with undercuts, allowing the mold to open and release the part.

Core Pull:

Extracts parts from the mold, often for parts with holes or recesses.

Side Core:

Moves within the mold cavity to mold parts with protrusions.

Expandable Cores:

Expands after injection to mold parts with shrinkage or complex shapes.

Rotating Mechanisms:

Enables structural transitions or repositioning for parts with moving components.

Insert Molding:

Inserts materials during injection to create composite structures.

Automatic Ejection:

Automatically removes parts from the mold, enhancing efficiency.

Injection Mechanism:

Injects molten plastic into the mold cavity, ensuring uniform filling.

Designing the draft angle and parting line of an injection mold is crucial to ensuring smooth mold opening and part ejection. Here are some common methods for designing the draft angle and parting line:

Determine the parting direction:

Firstly, it's necessary to determine the parting direction, which is the direction from which the part will be ejected from the mold. This will dictate the direction and location of the draft angle.

Design appropriate draft angles:

The draft angle is the angle between the mold cavity wall and the part surface, determining whether the part can be smoothly ejected from the mold during opening. Typically, the size of the draft angle depends on factors such as material elasticity and friction coefficient. In general, draft angles between 1° to 3° are common.

Design the parting line:

The parting line is the contact line between mold halves or sections, determining the position and alignment of the mold during closure. The design of the parting line should ensure full alignment of the mold halves and smooth closure, while avoiding part distortion or damage.

Consider draft force and surface quality:

When designing draft angles and parting lines, it's important to consider the force required for part ejection and the quality of the part surface. Proper draft angle and parting line design can reduce draft force while ensuring a smooth, scratch-free part surface.

Testing and optimization:

Before actual production, it's advisable to conduct mold trial tests to ensure that the draft angle and parting line design function correctly. Based on the trial results, adjustments and optimizations may be necessary to achieve optimal mold opening performance.

In summary, designing the draft angle and parting line requires consideration of multiple factors, including part design, material properties, and mold structure, to ensure smooth mold operation and the production of high-quality parts.