Extrusion Defined

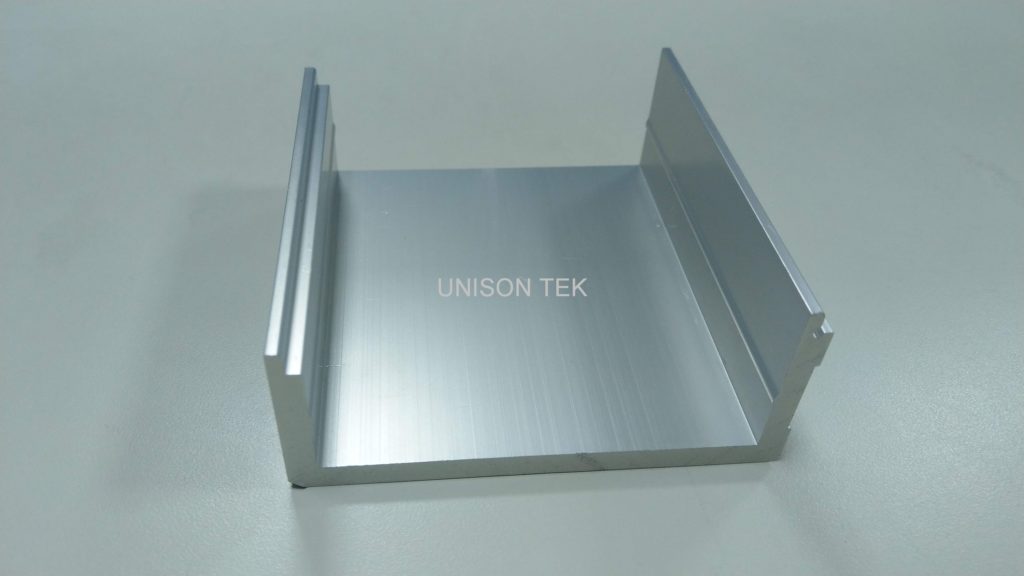

Extrusion is defined as the process of shaping material, such as aluminum, by forcing it to flow through a shaped opening in a die. Extruded material emerges as an elongated piece with the same profile as the die opening.

Technique of Aluminium Extrusion

Aluminum extrusion is a technique used to transform aluminum alloy into objects with a definitive cross-sectional profile for a wide range of uses. The extrusion process makes the most of aluminum’s unique combination of physical characteristics.

Its malleability allows it to be easily machined and cast, and yet aluminum is one third the density and stiffness of steel so the resulting products offer strength and stability, particularly when alloyed with other metals.

- The extruded part passes onto a run-out table as an elongated piece that is now the same shape as the die opening. It is then pulled to the cooling table where fans cool the newly created aluminum extrusion.

- When the cooling is completed, the extruded aluminum is moved to a stretcher, for straightening and work hardening.

- The hardened extrusions are brought to the saw table and cut according to the required lengths.

- The final step is to treat the extrusions with heat in age ovens, which hardens the aluminum by speeding the aging process.

Aluminum extrusion's endless opportunities. The advantages of aluminum are to a great extent based on their manufacturing method. Extrusion provides unique construction and design possibilities.

The extrusion process starts with ingots of aluminum alloy. We cut these into smaller logs, or billets, and heat them in an induction furnace to the right extrusion temperature.

The heated billet is forced through a die under great pressure, and the finished extrusion is squeezed out of the die like toothpaste from a tube. It is then cooled using air or water.

The Process of Aluminum Extrusion

The process of aluminum extrusion consists of the following steps:

- After designing and creating the shape of the die, a cylindrical billet of aluminum alloy is heated to 800°F-925°F.

- The aluminum billet is then transferred to a loader, where a lubricant is added to prevent it from sticking to the extrusion machine, the ram or the handle.

- Substantial pressure is applied to a dummy block using a ram, which pushes the aluminum billet into the container, forcing it through the die.

- To avoid the formation of oxides, nitrogen in liquid or gaseous form is introduced and allowed to flow through the sections of the die. This creates an inert atmosphere and increases the life of the die.