Introduction of Chamfer

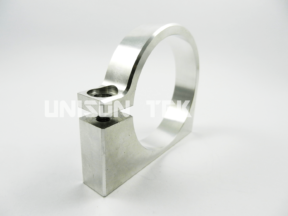

Chamfer is usually referred to as a 45˚ sloping edge that is key part of numerous designs, especially in industrial or architectural fields. Take vacuum cleaner for example, chamfering is used to exhibit the exquisite exterior of this product. On the hand, deburring means the removal of all rough edges and ridges after a finished product takes shape.

Performance:

Chamfering and deburring are important to the post-treatment process. When raw material is still attached to the product surface, chamfering and deburring serve the purpose to make the surface texture smooth and identical. Chamfering takes off pieces of raw material to prevent the part from injuring users and to make sure it can engage with the grooves of a specific part.

To what extent of chamfering and deburring is required depends on the design of each item and a manufacturer’s experience. Therefore, edge finishing involves removing sharp edges, undesired burrs, and then calculating chamfering, which are indispensable steps of post-treatment.

See our Facility and Inspection Equipment