Aluminum Extrusion Technology

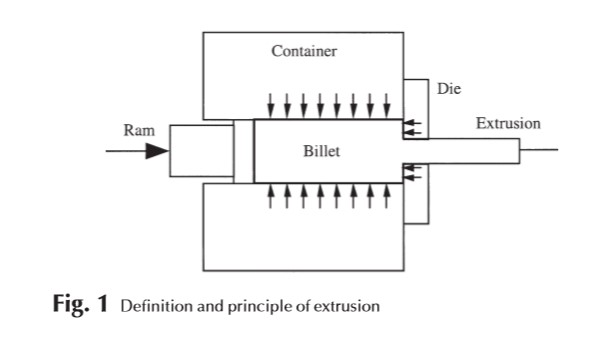

Extrusion is a plastic deformation progress in which a block of metal (billet) is forced to flow by compression through the die opening of a smaller cross-sectional area than that of the original billet as shown in Fig. 1.

Extrusion is an indirect-compression process. Indirect-compressive forces are developed by the reaction of the workpiece (billet) with the container and die; these forces reach high values.

The reaction of the billet with the container and die results in high compressive stresses that are effective in reducing the cracking of the billet material during primary breakdown from the billet. Extrusion is the best method for breaking down the cast structure of the billet because the billet is subjected to compressive forces only.

Extrusion can be cold or hot, depending on the alloy and the method used. In hot extrusion, the billet is preheated to facilitate metal deformation.

Feel free to contact us at: [email protected]

Tel: 886-2-2298-8665 #221