Introduction

Punching is a metal fabricating process that removes a scrap slug from the metal workpiece each time a punch enters the punching die. On the hand, Punching is also a forming process that uses a punch press to force a tool, called a punch, through the workpiece to create a hole via shearing.

Punching is applicable to a wide variety of materials that come in sheet form, including sheet metal, paper, vulcanized fibre and some forms of plastic sheet.

How Sheet Metal Punching Works

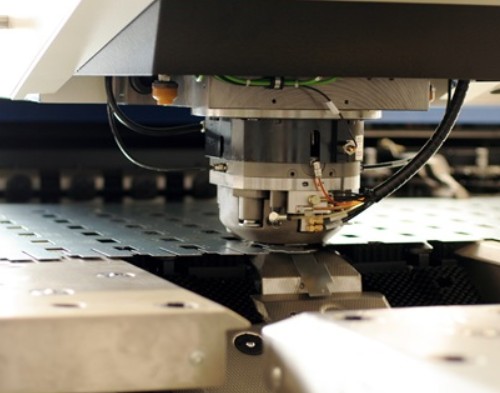

Modern metal punching is carried out by using heavy machinery, to create holes and indents in a piece of metal. The principle is relatively simple:

- The sheet metal being punched is sandwiched between the punch and a die.

- The punch moves downward and into the die. This causes the sheet metal underneath the punch to be sheared away from the surrounding material.

- Any cut metal is collected into a container for later use/recycling.

- Repeat steps 1-3 until the desired shape is achieved.

Get more info, please visit our CNC Turning Parts or Products.

Contact us for your customized metal parts.